Crystals, Human Organs, and suspensions that are out of this world.

If you are in certain circles, manufacturing in space is the latest craze everyone is talking about. But in all honesty most of the world is still asking the simple question “Why spend money to go to space at all?”. NASA has been doing a much better job evangelizing space travel in recent years, so I’ll leave answering that question in it’s entirety to them. In this post we are going to focus on just a single reason we should go to space… and the answer is MANUFACTURING!

!!!WARNING!!! Manufacturing in space might not be for you, at least not yet.

TOPIC INTRO

When it comes to conversations about manufacturing in space, the most-common thing I hear as a reason is simply “We use so much fuel getting off of earth, so it makes economic sense to start making our spacecraft in space”.

Other times it’s something more immediately practical, “3D printing components in space would save millions for space station repairs.”

… And whilst these are both true, it short sides the value for those of us here at home on earth. From a business perspective these answers alienate (yes, I did that 🙂) any company who doesn’t have furthering space travel as a business goal. That is most industries and 99.x% of all businesses.

So what’s in it for Earth? I’m happy to say, A LOT!

CRYSTALS

Now I’m not talking about the “Cubic Zirconia” kind of crystal, though as I’m typing this I could imagine a new market of “Space Diamonds” opening up. That would be kind of cool.

I’m talking about industrial crystals. Different industries use crystals in all sorts of ways. For instance, the medical research field uses the formation of crystals to isolate certain protein structures of interest that cause bacterial infections in humans. This research is pertinent in determining how best to treat these infections in order to save human lives.

Pure silicon crystals are another example. These are used to create solar cells, integrated circuits (phones, TVs), and many other products that use high performance semiconductors.

“Okay crystals are useful Mike, but how does space help?” Well without getting too “far out” 🙂, gravity introduces a number of imperfections or inclusions into a crystalline structure as it is forming here on earth. These inclusions often reduce the quality at which these crystals can perform. There is a tremendous effort in researching the best methods to further minimize these, and other imperfections, when forming crystals here on Earth. This research, and the methods it will produce, costs a considerable amount of money and will always have some degree of error. As space travel becomes more affordable, and more uses for super quality crystals come to light, growing these in space may prove to be the better option. Both in cost and quality.

3D PRINTING HUMAN ORGANS

Yes, you read that right. We are right on the cusp of some major breakthroughs in medical science around engineering living functional tissues (think arteries and valves first… but eventually entire organs such as hearts). One of the major hurdles right now in creating human organs is that a “scaffolding” is needed prop up the creation. This scaffolding holds the proper 3-dimensional shape of the organ, that scientists would then begin to grow human tissue around. Easy enough… so where’s the problem? Well, you now have a rigid structure inside of your nicely built organ, and that rigid structure really needs to not be there if you want the organ to work.

There is a TON of money being put into different “rigid” gels, and bio-inks that would provide an initial scaffolding during tissue growing cycle, and eventually overtime would be biologically replaced by the new cells being grown on it. I’m no expert, but I imagine this is a very difficult problem to solve.

Take a step back for a second though, and let’s ask ourselves a basic question. “What is the purpose of a scaffolding?” To keep the shape duh. Obvious enough, but let’s rephrase that answer in another frame of reference. The

scaffolding helps fight gravity to keep the organ’s desired shape. But what if we can eliminate gravity all together? This is where space comes into play.

3D printing an organ, human tissue, or really anything in space eliminates one of the major 4 forces that engineers and manufacturers have to overcome here on Earth. Gravity. No gravity, no major need for scaffolding, no costly scaffolding gels necessary.

There is a TON of money being put into different “rigid” gels, and bio-inks that would provide an initial scaffolding during tissue growing cycle, and eventually overtime would be biologically replaced by the new cells being grown on it. I’m no expert, but I imagine this is a very difficult problem to solve.

Take a step back for a second though, and let’s ask ourselves a basic question. “What is the purpose of a scaffolding?” To keep the shape duh. Obvious enough, but let’s rephrase that answer in another frame of reference. The scaffolding helps fight gravity to keep the organ’s desired shape. But what if we can eliminate gravity all together? This is where space comes into play.

3D printing an organ, human tissue, or really anything in space eliminates one of the major 4 forces that engineers and manufacturers have to overcome here on Earth. Gravity. No gravity, no major need for scaffolding, no costly scaffolding gels necessary.

SUSPENSIONS

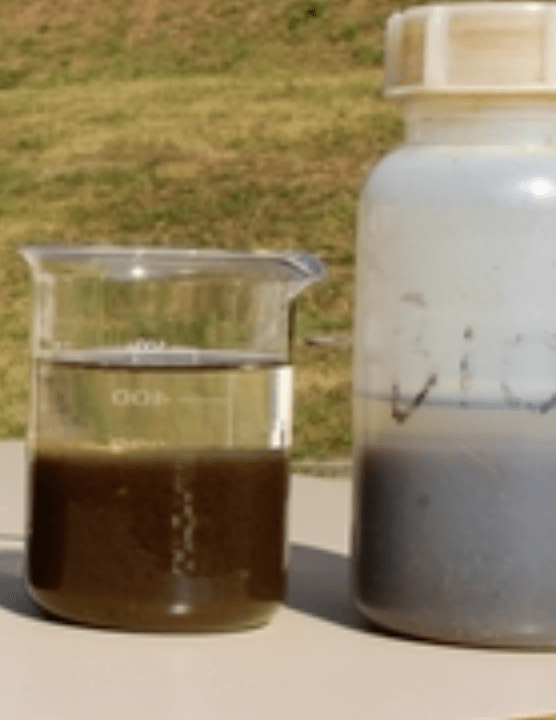

Before we jump into this one, it’s important we make a distinction between a suspension and a solution. Suspensions are simply a liquid with really small particles floating around in it. Think muddy water, or maybe more familiarly coffee. Solutions on the other hand involve chemistry, so we won’t touch that. This is just a 100 level class.

Here on earth, Millions on Millions of dollars are being spent on techniques to nullify the gravitational force acting on Suspensions in order to make them more uniform and effective. Suspensions are used in everything from medicine, to military vehicle armor, material science, and almost anything being cured.

“Gravity is the great enemy of all suspensions…”

Dr. Arthur H. Kibbe professor of Pharmaceutical Sciences at Wilkes Unv.

Dr Kibbe is referring to the fact that any suspension begins to lose its uniformity over time due to the force of gravity pulling the most dense particles to the bottom of the mixture, causing them to eventually ‘settle’.

This figure demonstrations a visual example of a settled suspension. The heavier particles overtime fell to the bottom of the liquid. If undisturbed long enough, there con be a very distinct separation line.

Let’s almost do some math. Don’t worry, I only put this here to show gravity’s relationship to the speed of Sedimentation. If you start to get classroom PTSD, just skip to the (1) two paragraphs down. To calculate the Sedimentation Speed Vg, we have this nifty formula.

This shows a basic calculation for sedimentation speed of a particle using stokes law. There are several parameters in this formula that here on earth affect a suspensions’ sedimentation rate such as: (d) diameter of the particle, (Δρ) differencein density between particle and liquid, and (η) viscosity of the mixture.

Take a look at what happens if (g) goes away, or in other words g=0. The Sedimentation speed then also goes to 0!

(1) This means there is no sedimentation takes place when there is no gravity, and that particles will stay in a mostly uniform solution indefinitely! To those trying to make uniform solutions, especially during processes like curing, this is AMAZING NEWS! No more need to thicken the suspension with additives, or deploying other more obscure and costly scientific approaches. Space does it for you!

Note: there are other smaller forces (electro-magnetic for example) that may affect the uniformity of a suspension that I’m ignoring in this discussion. These are all somewhat unique to each suspension, while the force of gravity is uniform across them all.

So what does this mean practically?

My gut tells me that there are many specialized use-cases around suspensions and curing, that are not evident to the laymen. I would love to open this topic up for discussion. If you have any thoughts or ideas, take a few moments to contribute in a comment or a DM!

I would love to open this topic up for discussion. If you have any thoughts or ideas, take a few moments to contribute in a comment or a DM!

I was able to pull together a few applications.

- An ability to cure 3 dimensional resin structures without scaffolding

- Create incredibly thin resins/epoxies which have deeper penetration to surfaces when they are used as a protective coating.

- Create incredibly precise foams/substrates, such as the metal foams being used by the military today as a lightweight absorbent alternative to plate sheet armor. These can provide the strength of a plate of metal at less than 50% of the weight. In space, foam structures could be created with even more precision, possibly increasing their effectiveness.

OUTLOG

Is the technology ready today? The answer is both yes and no. First off, let’s keep in mind that getting a factory up and running terrestrially (on Earth) can take up to 4 or 5 years. With that said, let’s be less concerned about whether technology is ready today, and more precisely consider whether technology will be ready in a 5 year time frame. I believe the answer is an overwhelming yes!

I’ll leave you with a more immediate use-case to satisfy the palate.

3D Printing parts for space station repairs – Yes, that is manufacturing!

I would love to hear your thoughts! A sincere thank you for your time. I hope that this was both a fun and informative read! I am no expert in crystalline science, solution curing, or human organ creation… but I am a curious person who’s set some time aside to follow the latest trends in space exploration! We live in a truly amazing time.

Author: Michael D. Patton

In today’s world, where information is readily available at our fingertips, it’s easy to get caught up in the vast sea of data without paying attention to its credibility. This is where citing sources becomes essential. With so much misinformation circulating on the internet, it’s crucial to know where your information comes from and to ensure it’s reliable.

This bibliography serves as a testament to the importance of citing sources in today’s world.

— Bibliography —

NASA. “The Value of NASA.” Accessed March 13, 2023. https://www.nasa.gov/specials/value-of-nasa/.

NASA Jet Propulsion Laboratory. “20 Inventions We Wouldn’t Have Without Space Travel.” Accessed March 13, 2023. https://www.jpl.nasa.gov/infographics/20-inventions-we-wouldnt-have-without-space-travel.

“New Tissue Engineering Process Brings Lab-Grown Organs One Step Closer.” Drug Target Review, October 17, 2019. https://www.drugtargetreview.com/news/81080/new-tissue-engineering-process-brings-lab-grown-organs-one-step-closer/.

Fierce MedTech. “How Far Are We from Lab-Grown Organ Transplants? Y Combinator Startup Printing a Road Map.” Fierce MedTech, April 12, 2018. https://www.fiercebiotech.com/medtech/how-far-are-we-from-lab-grown-organ-transplants-y-combinator-startup-printing-a-road-map.

Lee, Junmin, and Deok-Ho Kim. “Printing Your Way Out of Trouble: How Bioink Could Revolutionize the World of Transplants.” Chemical Reviews 120, no. 21 (2020): 11765-11789. https://doi.org/10.1021/acs.chemrev.0c00084.

Scienceline. “What Are Some Uses of Crystals in Science?” Accessed March 13, 2023. http://scienceline.ucsb.edu/getkey.php?key=1229.

Wall, Mike. “Magnetic Gravity Trick Grows Perfect Crystals.” New Scientist, January 14, 2008. https://www.newscientist.com/article/dn12467-magnetic-gravity-trick-grows-perfect-crystals/.

Flottweg SE. “Sedimentation Speed.” Accessed March 13, 2023. https://www.flottweg.com/wiki/separation-technology/sedimentation-speed/.

Kibbe, Arthur H. “Lecture 7: Sedimentation.” Accessed March 13, 2023. https://web.wilkes.edu/arthur.kibbe/lecture7.html.

Chen, Yong, and Xiaosheng Gao. “Curing 3D Objects with the Acceleration Effect of Fluid Sedimentation.” Journal of Manufacturing Processes 26 (2017): 212-220. https://doi.org/10.1016/j.jmapro.2016.12.008.

European Space Agency. “Space Fluid Oddities.” Accessed March 13, 2023. https://www.esa.int/Education/Space_In_Bytes/Space_fluid_oddities.

ASME. “Metal Foam Stops Bullets.” Accessed March 13, 2023. https://www.asme.org/topics-resources/content/metal-foam-stops-bullets.

Huang, Shih-Huang. “Foamable Metal Composition and Method of Making.” U.S. Patent No. 6,698,331 B1, March 2, 2004. https://patents.google.com/patent/US6698331B1/en.